Sustainable composite materials for vehicles of the future

The Luxembourg Institute of Science and Technology creates sustainable composite materials fulfilling the needs of transport equipment manufacturers.

Lena Mårtensson

Lena Mårtensson

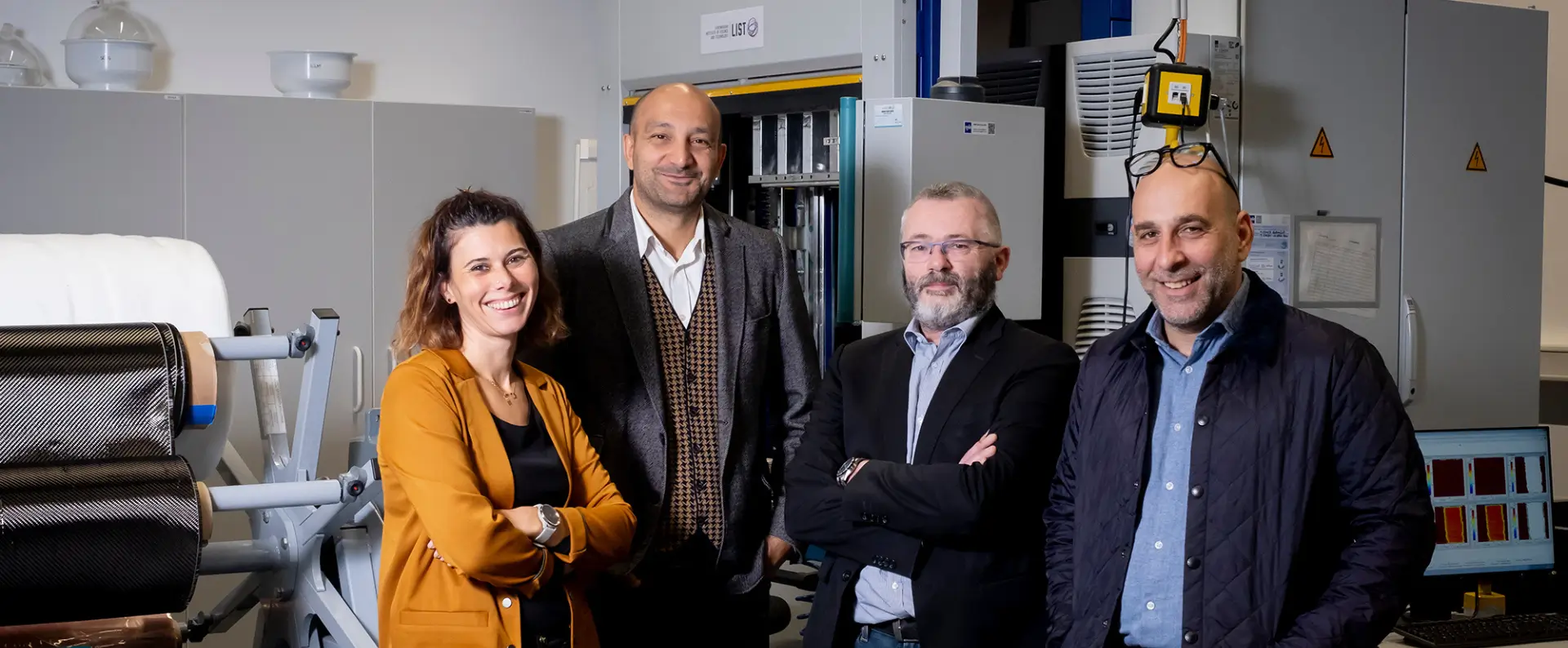

The transport industry plays a key role in society’s efforts to reduce greenhouse gas emissions. An essential element for success is the availability of ultra-lightweight, recyclable materials with a low carbon footprint. The Sustainable Composites Material & Manufacturing (SCMM) Innovation Centre of the Luxembourg institute of Science and Technology (LIST) develops sustainable composite materials to meet the evolving demands of tomorrow’s road, rail, space and aeronautic vehicles.

Industry partnership

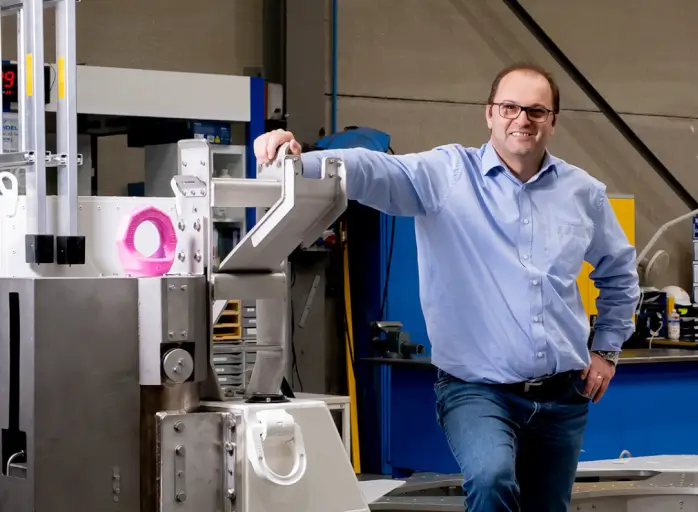

The work of the SCMM is carried out in close cooperation with industry partners. “Our current research agenda is driven by concrete market needs articulated by three major transport OEMs (original equipment manufacturers): Toyota, Airbus and Thales Alenia Space,” explains Thierry Girot, Core Technologies Leader at LIST and the SCMM coordinator. “We are currently expanding our technology portfolio through the addition of new OEMs, like IVECO Group, and tier suppliers active in transport sectors as well as with new members working in the composite value chain. We recently welcomed Kordsa and DowAksa, two major materials suppliers within the composite industry. Our objective is to further develop lightweight, sustainable composite solutions aligned with specific requirements and constraints in terms of costs, production processes and so on.”

Our mission is to develop lightweight, sustainable composite materials aligned with their specific requirements and constraints.

Thierry Girot, Luxembourg Institute of Science and Technology

The SCMM aspires to deliver demonstrators that will be integrated into vehicles. “We work on a range of demonstrators, including automotive components based on natural fibre composites, recyclable hydrogen tanks for the automotive sector, interior components for the aircraft industry, and easily assembling and repairable panels for space applications,” says Dr Girot.

Entire sustainable composite materials value chain

To build these demonstrators, the team of material experts conducts research and technology development along the entire composites value chain, spanning from raw materials development to manufacturing, joining to end-of-life treatment of the components. “Our partners find our value chain approach unique. While developing lightweight and sustainable composites parts, we have in-house capabilities for developing sustainable fibres and fillers as well as chemistry skills enabling us to develop our own innovative resin systems allowing improved performance, durability and end-of-life recyclability towards full circularity. This unique set of assets attracts a lot of attention from industry,” Dr Girot points out.

The focus is on developing biobased composite materials while also using eco-friendly processes that combine low energy consumption with reduced waste and safe chemicals. The researchers work to define how complex composites parts can be disassembled to facilitate the reuse of components at the end of its lifespan.

Our partners find our value chain approach unique. Our set of assets attracts a lot of attention from industry.

Thierry Girot, Luxembourg Institute of Science and Technology

Work starts at low technology readiness levels, for which the LIST’s Materials department has its own research agenda including technologies with a higher element of risk. “Within the SCMM, we don’t conduct any blue-sky research: we use technologies that have already been demonstrated at the lab scale and turn them into solutions that will take industry a step further,” says Dr Girot. “One example is natural fibres, a bio-based feedstock already used by the automotive industry for less demanding applications such as panels for the interior of passenger cars. We have been able to demonstrate and patent technologies where the performance of bamboo fibre is much higher and could potentially be used for more demanding applications such as exterior or load bearing applications. LIST is actually at the forefront in this field.”

Calling transport OEMs and their suppliers

As the technology readiness levels of the technologies increase and move closer to market application, the cooperation with the SCMM’s partners intensifies. “The OEMs set the scene, but it is crucial that we involve their suppliers, who will ultimately produce and sell the components integrating our composite materials. This is why national and international stakeholders such as Euro-Composite, Gradel, DowAksa and Kordsa are part of our initiative. We invite companies worldwide involved in the polymer and composites supply chain – from raw material suppliers to tier suppliers – to contribute with their technologies and be part of shaping and implementing the demonstrators and testing them in relevant conditions,” Dr Girot underlines.

We invite companies worldwide involved in the polymer and composites supply chain to be part of shaping and implementing the demonstrators and testing them in relevant conditions.

Thierry Girot, Luxembourg Institute of Science and Technology

Although the SCMM specifically targets the transport sector, the developed technologies can be applied to domains beyond that field. “Our technologies can meet the needs of other industries as well. Anyone interested in cutting-edge composite materials is welcome to contact us to explore how they could apply our solutions.”

Photo credits: Luxinnovation/Jessica Theis